Pallet Racks for Warehouses: Efficient Storage Solutions for Every Need

At Norlift, we provide pallet racking systems tailored to your specific storage requirements. From bulk storage racks for hand-loaded applications to heavy-duty pallet racks for forklift-loaded needs, we have you covered. Our selection includes cantilever racks, carton-flow racks, push-back racks, and drive-in racks to optimize your warehouse operations. We carry a wide inventory of new pallet racks and offer a variety of used pallet racks for sale, ensuring cost-effective options for every budget.

Not sure how to maximize your warehouse space? Our team of experts can design a warehouse pallet rack design that fits your application and budget perfectly. Contact Norlift in Spokane today to learn more about our affordable and durable storage solutions.

What is Pallet Racking?

Pallet racks are versatile warehouse storage systems designed to hold palletized items on multiple levels of horizontal shelving. These systems maximize vertical space and improve efficiency by allowing forklifts to quickly load and unload materials.

Advantages of pallet racking include:

Enhanced vertical storage capacity.

Improved warehouse organization.

Faster material handling processes.

Key Components of Pallet Racks

Upright Frames

These are the vertical supports of the system, featuring punched holes (teardrop, keyhole, or T-shaped) to connect with the horizontal beams. Available in various heights and widths, adjustable pallet racks make it easy to accommodate different pallet rack dimensions and weight capacities.

Cross Beams

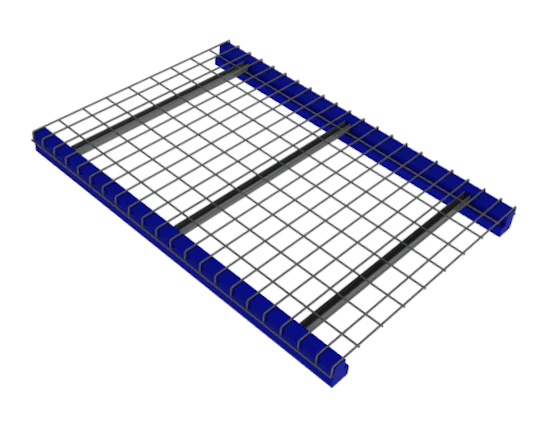

Cross beams are heavy-duty rails that create the horizontal shelves. They come in step beams or box beams, which support a wide range of pallet weights. Adding pallet racks with wire decking provides additional support and ensures safety by preventing items from falling through.

Supporting Components

These include anchor bolts to secure the racks, row spacers for stability, and decking for added support. Each component is vital to maintain the pallet rack weight capacity and overall system integrity.

Wire Decking for Pallet Racks

Wire decking enhances the safety and functionality of your pallet rack shelving. It provides better air circulation, prevents product falls, and complies with fire safety regulations by allowing sprinkler systems to function effectively.

Styles of Wire Decking

Flared/Universal Decking

Compatible with most types of beams, including structural pallet racking and selective systems.

U Channel Standard Decking

Ideal for standard beams with inside steps, offering extra strength.

Inside Waterfall Decking

Keeps beam faces clear for barcoding and labeling.

Types of Pallet Racking Systems

Roll-Formed Pallet Racks

Known for their teardrop-shaped holes, these racks are highly versatile and compatible with other systems. Their clip-on beams make adjustments and reconfigurations simple, making them a popular choice and for expanding existing setups.

Structural Pallet Racks

Built for heavy-duty applications, these racks feature bolted connections for added strength and durability. They can support significantly more weight than roll-formed racks, making them ideal for industries requiring heavy-duty pallet racks.

Expert Pallet Rack Installation & Support

Norlift’s experienced team ensures that your pallet rack installation is completed efficiently and safely. Our experts also provide guidance on pallet racking safety tips, selecting the right pallet rack accessories, and choosing a system that meets your needs.

Whether you’re looking for cheap pallet racks, durable used pallet racks for sale, or a fully customized warehouse pallet rack design, we are your trusted pallet racking suppliers. Give us a call to find the right pallet racking for your operation today!

Not sure what brand you own? Click here to find out!

Products carried:

Brands carried:

Drive-in Rack

Gravity Rack

Mezzanines

Package Rack

Guard Rails

Carton Flow Rack

Pallet Frames

Pallet Rack

Push Back Rack

Stack Rack

SpaceRak

Hannibal

Jaken

Unarco